Driven by Precision,

Defined by Quality.

Driven by Precision,

Defined by Quality.

Our Capabilities

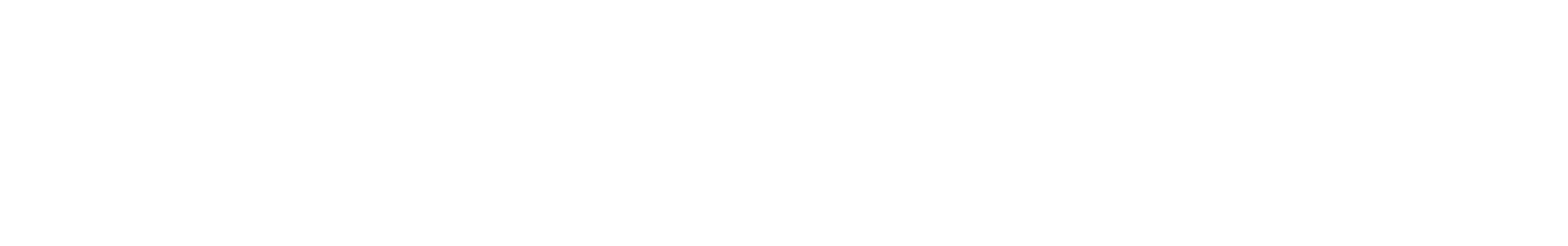

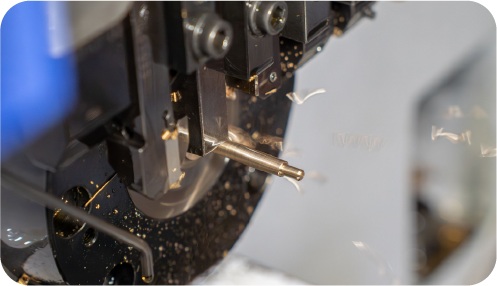

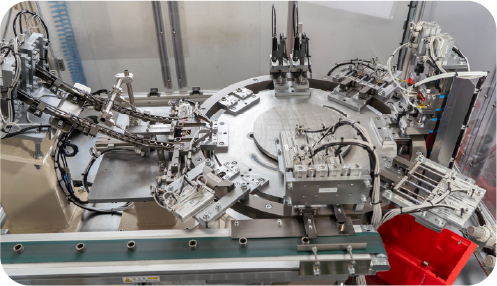

Akita’s manufacturing ecosystem blends proven machine platforms with adaptive tooling and digital oversight.

Our Capabilities

Core Technologies

Precision in Action.

About Akita Co., Ltd.

Built,

Not Inspected.

In Osaka, 1957, Akita Co., Ltd. began with a simple belief: quality is built, not inspected. Incorporated in 1966, that belief evolved into a discipline—monozukuri—where process, people, and precision move as one. What started in a small workshop now powers global industries, yet our mindset remains unchanged: look closer, refine further, and let the craftsmanship speak for itself.

About Akita Co., Ltd.

Built,

Not Inspected.

In Osaka, 1957, Akita Co., Ltd. began with a simple belief: quality is built, not inspected. Incorporated in 1966, that belief evolved into a discipline—monozukuri—where process, people, and precision move as one. What started in a small workshop now powers global industries, yet our mindset remains unchanged: look closer, refine further, and let the craftsmanship speak for itself.

Occupational

Safety,

Health &

Environmental Policy.

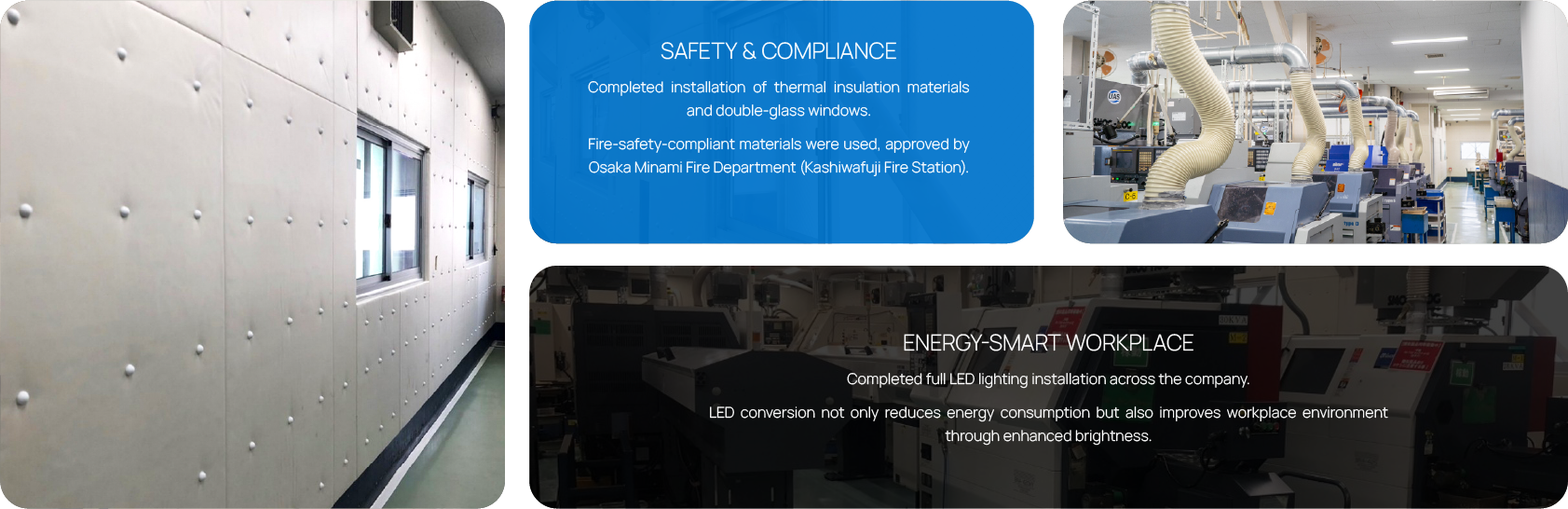

As a responsible member of society, we act with integrity and transparency, and remain committed to compliance across our organization and with all stakeholders.

We are committed to eliminating hazards and reducing occupational health and safety risks associated with workplace accidents. By fostering a strong safety culture, we aim to create an open, healthy, and comfortable work environment where all employees are mindful and actively engaged in decision-making.

We aim to address global challenges such as climate change and environmental pollution by promoting the protection of human life and health, advancing industrial development, and fostering a safe and secure society.

As a responsible member of society, we act with integrity and transparency, and remain committed to compliance across our organization and with all stakeholders. We are committed to eliminating hazards and reducing occupational health and safety risks associated with workplace accidents. By fostering a strong safety culture, we aim to create an open, healthy, and comfortable work environment where all employees are mindful and actively engaged in decision-making.

We aim to address global challenges such as climate change and environmental pollution by promoting the protection of human life and health, advancing industrial development, and fostering a safe and secure society.

How AKITA Solves

Your Manufacturing Challenges.

- Hard to find factories that can handle both small-lot and mass production

- Multiple processes (machining, forging, heat treatment, surface finishing) are scattered across suppliers, causing delays

- Quality inconsistency without strict inspection system

- Communication gap due to technical complexity

- Flexible production: from prototypes, small lots to mass production

- One-stop service: machining, forging, heat treatment, plating & anodizing via our trusted network

- Advanced QC system with precise inspection equipment

- Direct engineering communication & 50+ years of expertise

Vendor Code of Conduct & ESG Progress

ESG Progress

Confirmed by

ISO Audits

What Akita do for ESG?

Workplace

Environment

Keep In Touch

Connect

With Us

We’re ready to assist with your next project or inquiry — contact our team today.